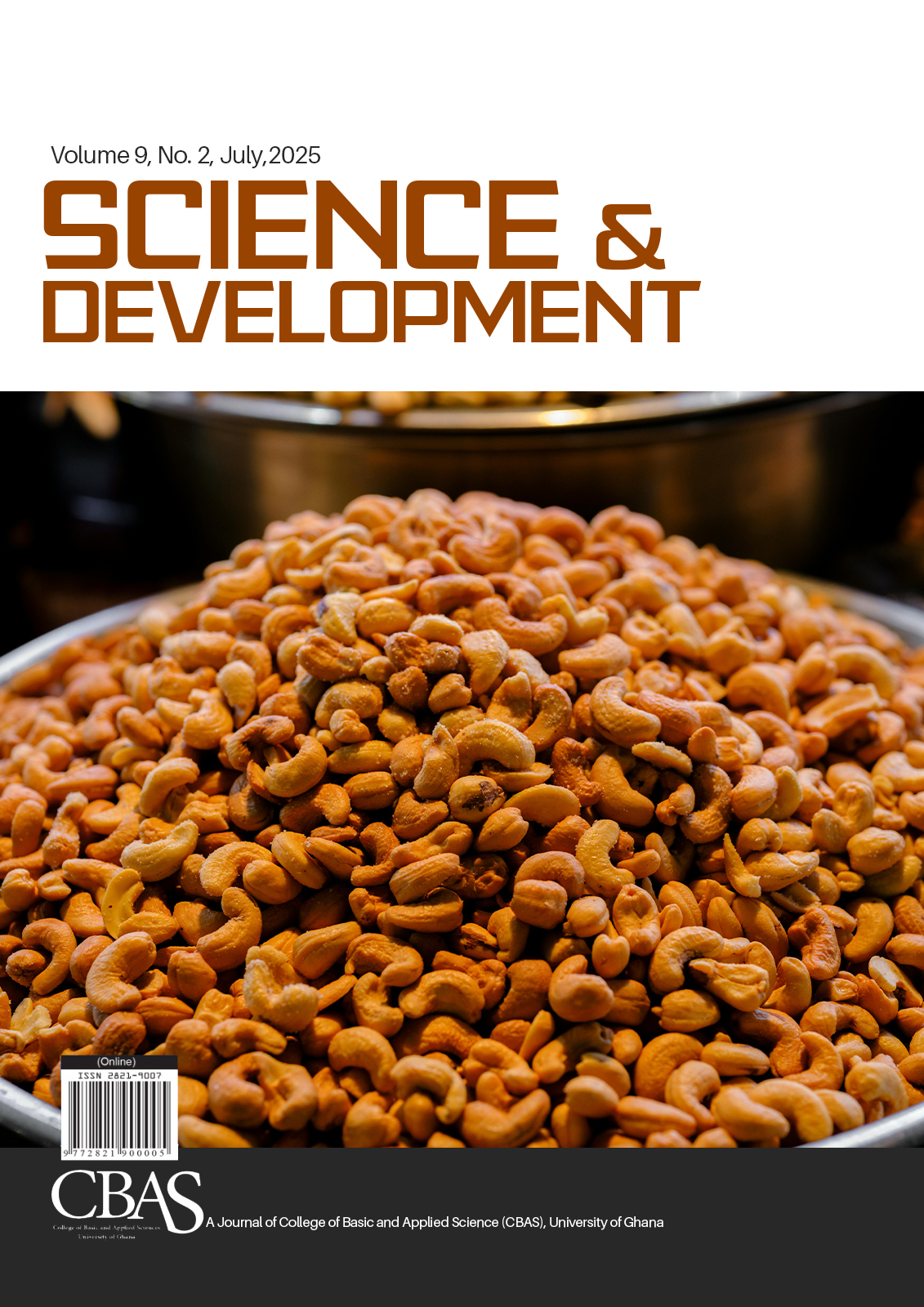

Optimization Of Process Variables to produce whole Cashew Kernels using Response Surface Methodology

Abstract

Cashew (Anacardium occidentale) is a vital economic crop on the international market. Thermal processing, specifically drying and steaming is the adopted preservation technology in making this cash crop available all year round. This research involves critical study of the unit operations required in the dehulling of whole cashew nut and makes attempts to reduce the persistent high breakages encountered through process optimization via response surface methodology (RSM). The steaming time, drying time, drying temperature, and shaft speed applied during dehulling are the operational parameters that were studied to determine their effects on the moisture content and breakage rate of cashew kernels. These factors were optimized to produce whole cashew nut kernels through RSM with five-level-four-factor full factorial central composite design (CCD). The optimum conditions were found to be 30 mins of steaming, 8 mins of drying time at a drying temperature, of 85oC and a shaft speed of 100 rpm. Applying these optimum conditions resulted in moisture content of 4.2% and breakage rate of 3.13%, meeting the Association of Food Industries (AFI) standards for cashew nuts. This exploratory research aims to help cashew nut processing companies to effectively reduce the high loss of whole kernels encountered during processing for sale. Consequently, aid in the reduction of processing cost and conserve resources, thereby maximizing overall operational gain.